Avant Tbd Catalyst Manufacturing China Selective Hydrogenation Catalyst Custom Sulfur Recovery Tail Gas Hydrogenation Scot Catalyst

Overview Shandong Avant New Material Technology Co., Ltd. Add: Chuangye Building 811, Beijing Road, Zhangdian, Zibo, Sha

Description

Basic Info

| Model NO. | Hydrogenation SCOT Catalyst |

| Application Industry | Industry |

| Product Name | Hydrogenation Catalyst |

| Use | Hidrotreating Catalyst |

| Components | Al2O3/Coo/Moo3 |

| Size | 1/6 |

| Bulk Density, Lb/FT3 | 52 |

| Working Temperature(ºC) | 280 |

| Working Pressure(Psig) | 3.5 |

| Vapour Flow(Lb/H) | 185546 |

| Molecular Weight( Lb/Lbmol) | 24.5 |

| Density at Working Temperature(Lb/FT3) | 0.042 |

| Features1 | High Strength |

| Features2 | Long Service Life |

| Features3 | High Hydrogenation Activity |

| Features4 | Organic Sulfur Hydrolysis Activity |

| Features5 | Activated Alumina as The Carrier |

| Transport Package | Pallet |

| Specification | 25kg/bag |

| Trademark | Avant |

| Origin | Shandong, China |

Product Description

Shandong Avant New Material TechnologyAdd: Chuangye Building 811, Beijing Road, Zhangdian, Zibo, Shandong, ChinaProduct DescriptionProduct Parameters

Technology Index:

| Item | Value |

| use | Hydrotreating Catalyst |

| Components | Al2O3/CoO/MoO |

| Size, in | 1/6 |

| Bulk Density, lb/ft3 | 52 |

Process Condition Reference;

| Working Temperature | 280 |

| Working Pressure | 3.5 |

| Vapour Flow | 185546 |

| Molecular Weight | 24.5 |

| Density at Working Temperature | 0.042 |

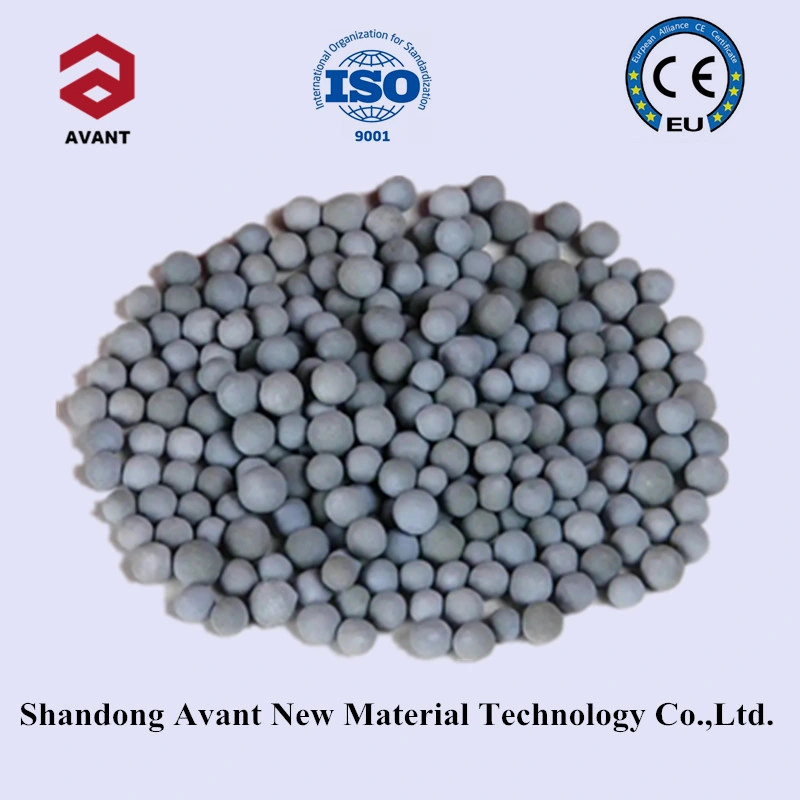

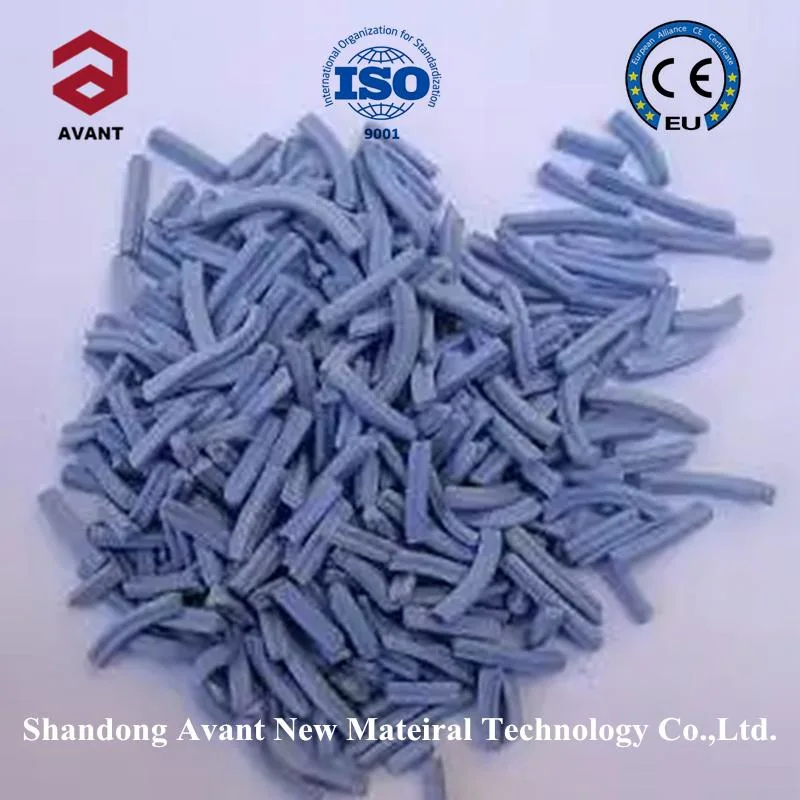

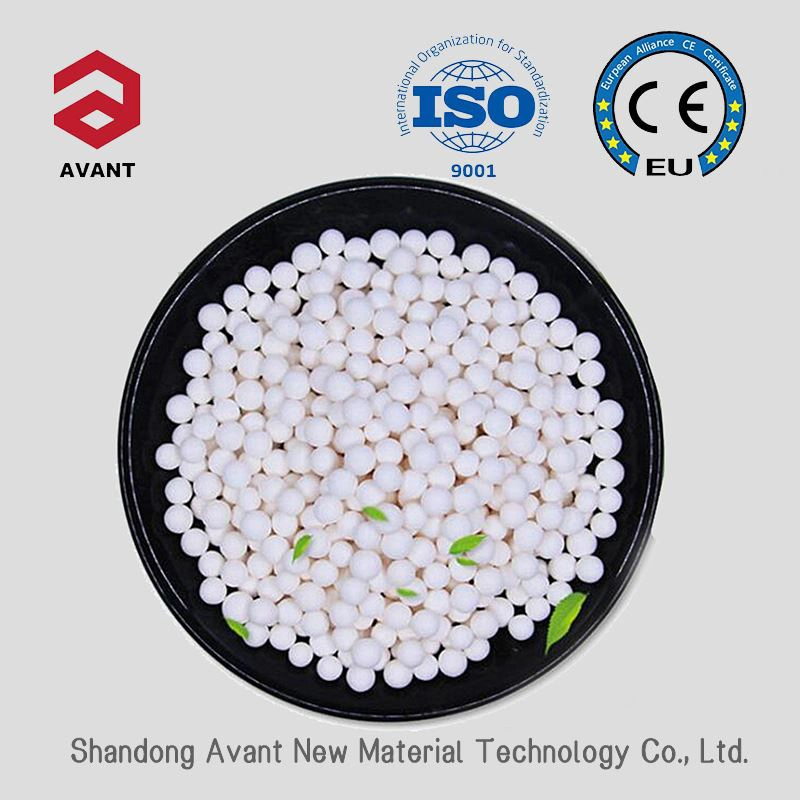

Avant Tbd Catalyst Manufacturing China Selective Hydrogenation Catalyst Custom Sulfur Recovery Tail Gas Hydrogenation SCOT Catalyst Detailed Photos

FAQQ2: Do you support OEM or ODM customized services?A2: A2: Yes, we support it. Welcome to our production base for a factory tourQ3: What trade terms and payment methods do you support?A3: Usually, we use the trade terms commonly used in the industry such as EXW/FOB/CIF for transactions, and collect payments through TT, wire transfer, Western Union, etc. However, the specific cooperation methods can be negotiated amicably by both parties.

Our Contact

Send now